Project of the Month

"Four-Day Efficiency Sprint"

From Bottleneck Discovery to Shipment Assurance

KEY FIGURES

- 13% increase in line productivity within one week

- improvement on-time delivery performance from 89% to 95%

BACKGROUND

- A leading furniture manufacturer responsible for shipping fully assembled units was consistently missing its takt-based output on the final assembly line, causing:

- Under-utilized delivery routes and rescheduled transport tours.

- Customer dissatisfaction and expedited freight fees to meet deadlines.

- Escalating labor costs due to overtime and shift disruptions.

- Despite having a KPI-driven dashboard and a motorized conveyor, all tasks on the line remained manual, leading to high variability and hidden delays. Our client challenged us to deliver a root-cause analysis and deploy initial countermeasures in just four days.

APPROACH

- Company Introduction (Onboarding):

Met with production planners, supervisors, and operators to learn how daily schedules were made, how the assembly line was set up, and what each workstation did. - Shift Observation:

Spent full shifts on the plant floor to watch work in real time and spot where work was backing up (bottlenecks). - Root-Cause Analysis:

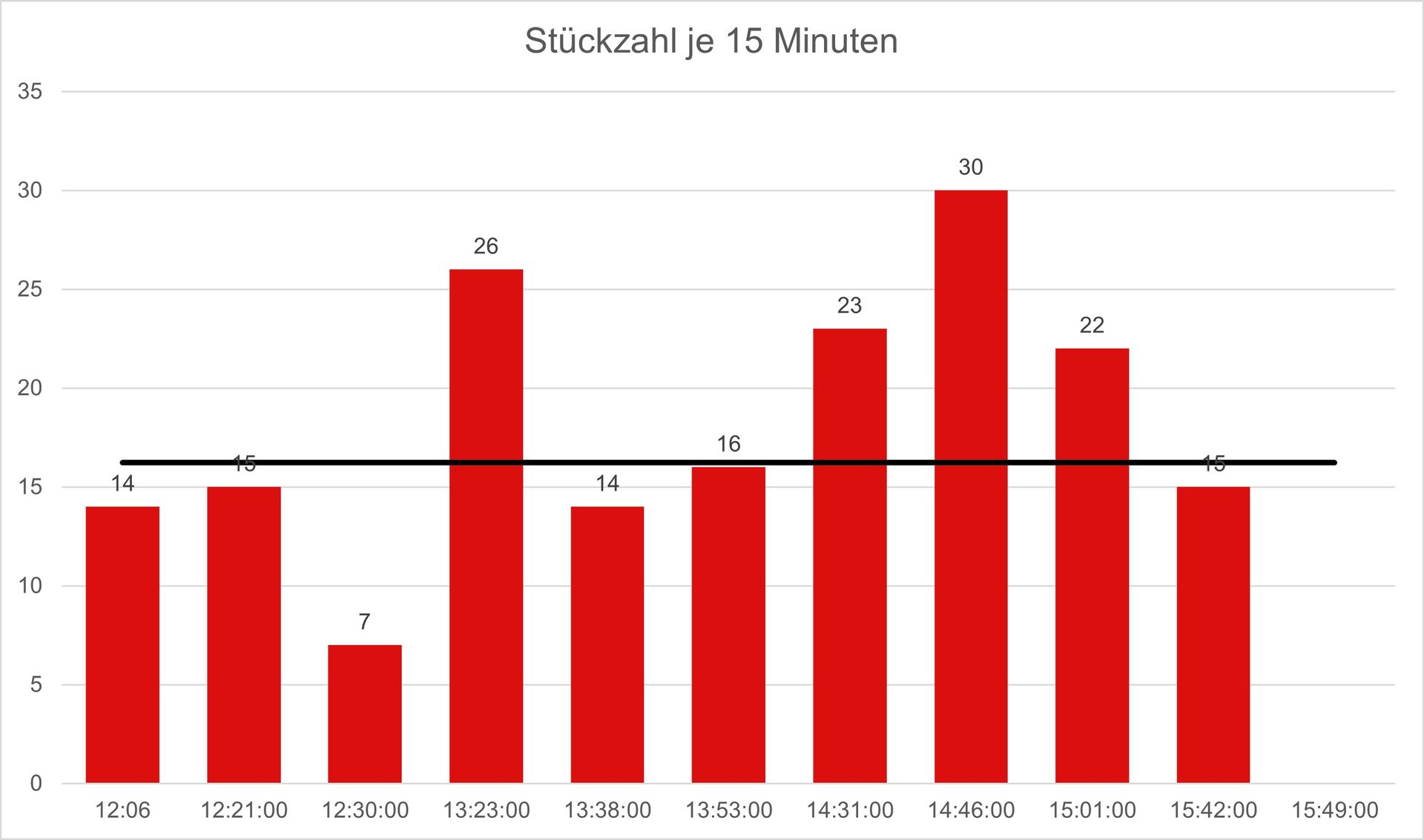

- 15-‑Minute Interval Monitoring: Recorded how many units were completed every 15 minutes to see patterns in slowdowns.

- Multi-Moment Sampling: Randomly checked what tasks operators were doing throughout the shift to measure how much time was spent on value-added work versus delays.

- Simple Time Studies: Timed specific tasks from start to finish to find out which steps varied the most.

- Workflow Observations: Noted unplanned stops, tool changes, material shortages, and any awkward or unsafe movements slowing down work.

- Data Analysis and Prioritization:

- Compiled the collected data and used simple charts (Pareto diagrams) to identify the single slowest workstation.

- Determined the leading causes of delay: lack of ready parts, inconsistent worker coverage, and missing visual instructions.

- Action-Plan Development:

Created a list of quick, low-cost changes ("quick wins") that could be put in place immediately. - Implementation of First Measures:

- Installed clear, picture-based instructions at each station.

- Introduced pre-packed parts in easy-to-reach bins to cut down on searching.

- Adjusted break times and shift handovers to ensure the busiest station always has sufficient staff.

- Added simple visual tools (e.g., colored bins and notice boards) to show when a station was about to run out of work.

- One-Week Follow-Up:

Conducted a weekly status review call with the production team to compare initial implementation results, share early outcomes, and adjust the measures as needed.

CUSTOMER BENEFITS

- Identified the takt-determining bottleneck at a specific workstation through shift observations.

- Demonstrated that meeting the required output was possible by actively managing the bottleneck.

- Provided supervisors with targeted training to recognize and address production constraints.

- Partnered with production leaders to implement a structured bottleneck-management system.

- Adjusted staffing allocations several times per day based on real-time bottleneck data.

- Increased line performance by approximately 10% within the first week.

- Improved on-time shipping reliability, leading to higher customer satisfaction

This four‑day sprint not only closed the immediate performance gap but also established a robust framework for sustainable, data‑driven operational excellence.